It has always been a challenge to work with bright (and therefore loud) devices in acoustically sensitive rooms. Those responsible for film, television, studios, theaters, opera and conference room equipment are confronted with this problem every day.

VICOM has been developing and building soundproof housings, also called silencers or silent boxes, according to customer requirements for over 15 years. The requirements are determined by the customer. We design and build the appropriate soundproofing case, but no device is too big, too heavy or too loud for us.

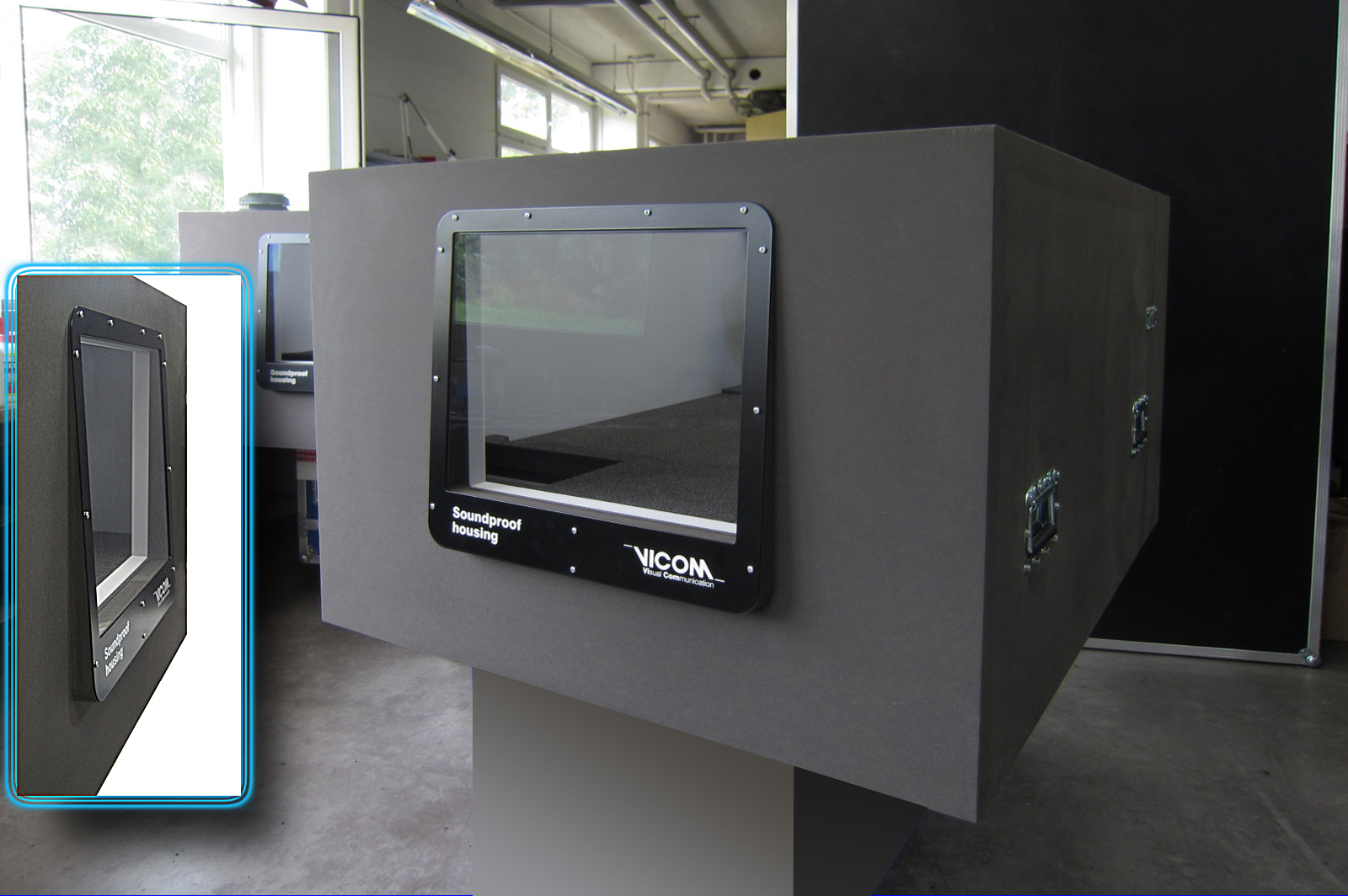

On the right in the picture you can see a soundproof enclosure made for the Bolshoi Theater, Moscow.

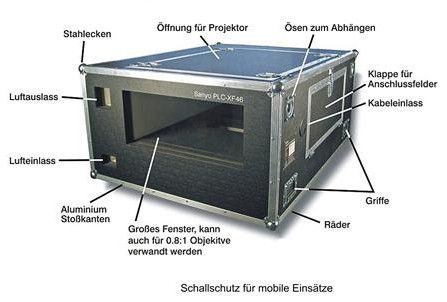

Soundproof housing

Experience and specialist knowledge in the area of sound insulation

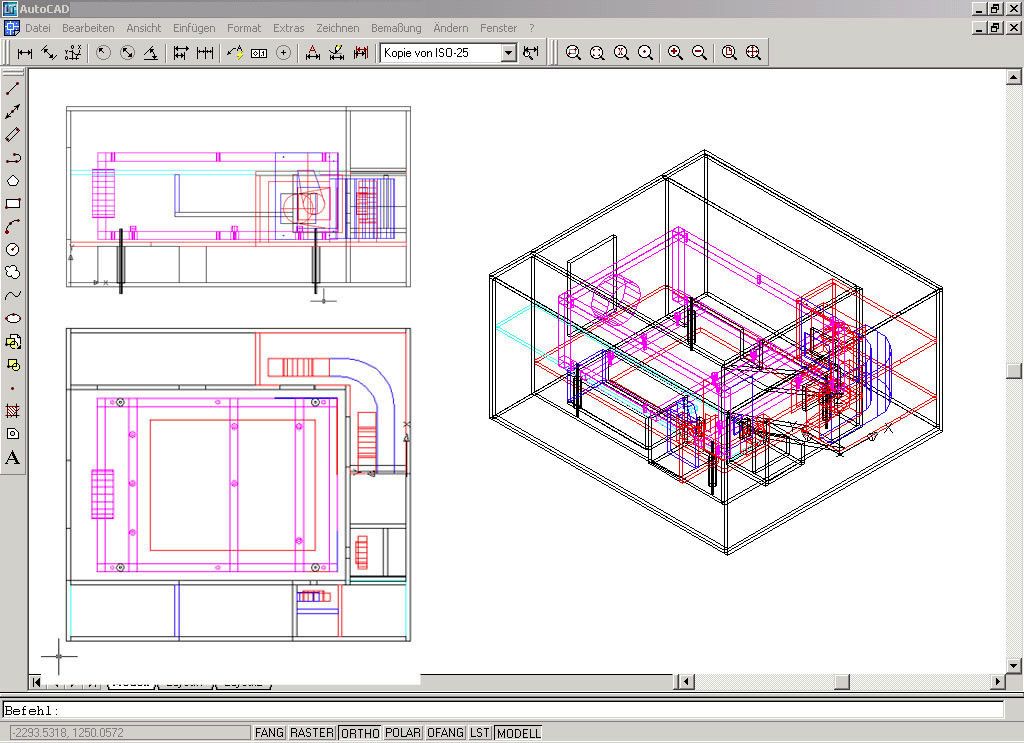

In addition to the extreme noise insulation, sufficient ventilation of the projector is the most important criterion right from the design stage. That is why the air flow simulation is carried out on the monitor during the CAD design. We then produce the soundproof housings as individual pieces according to customer requirements or as small series.

The photo shows a CAD design with airflow calculations.

Features

Soundproof housings for heavy projectors that are suspended require special technology to accommodate the weight.

A frequently used option is to insert steel strips into the housing. The steel strips are comprehensively mounted in milled grooves on three sides. The force is then absorbed via the hanging eyelets. Lifts are also used as an alternative to steel belts. Of course, these must then have the necessary load capacity.

As standard, the VICOM soundproof housings are equipped with a 3mm front panel made of acrylic glass. These offer sufficiently good projection quality, and there is practically no risk of breakage in everyday use. In order to achieve the optimized, maximum possible luminous efficacy of the projection with the lowest light loss, instead of the acrylic glass, we optionally offer a special projection glass with anti-reflective coating on both sides, which is also installed at an angle in the housing. This further minimizes reflections and therefore light loss.

VICOM soundproof housings all have an extremely high insulation value

- Optimal air circulation and active protection of the projector against “heat death”

- No structural changes are made to the projector

- Housing design as a protective flight case (for mobile use) or for fixed installations (conference rooms)

On the left in the picture you can see how the corresponding frequencies for a Christie projector are filtered out using multilayer foams.

All common projector series have been carefully analyzed by VICOM and are available as standard solutions. This particularly applies to projectors

- Christie

- Barco

- Panasonic

- Digital projection

- Epson

- NEC

- Vivitek

The list is constantly expanding with new projector models.

Optional equipment

- Protective flight case to transport the integrated soundproof housing

- Flying eyes for suspended use

- Rolling version with lockable brakes

- Ceiling and wall mount

- Integrated black shutter

- Swivel mirrors

- Externally accessible air filter

- Adaptations for lifts

- Coloring according to customer specifications (particularly important for permanent installations)

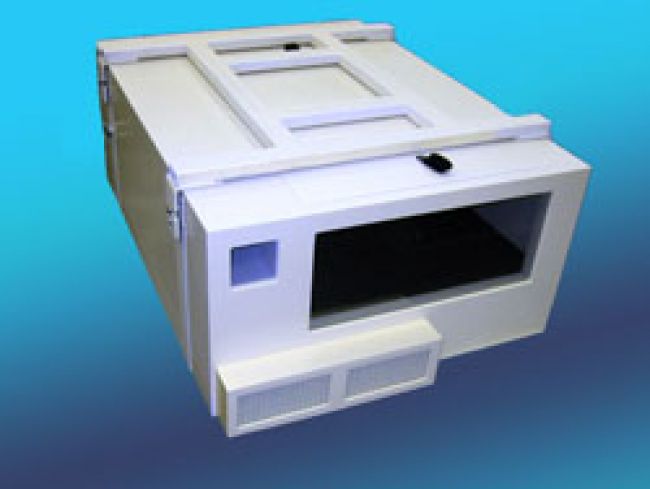

Series production

VICOM produces soundproof housings in series or as one-off production. It is important that the result of the sound insulation is optimal and that the housing is integrated into the room as best as possible and is designed to be robust for travel purposes.

Other areas of application

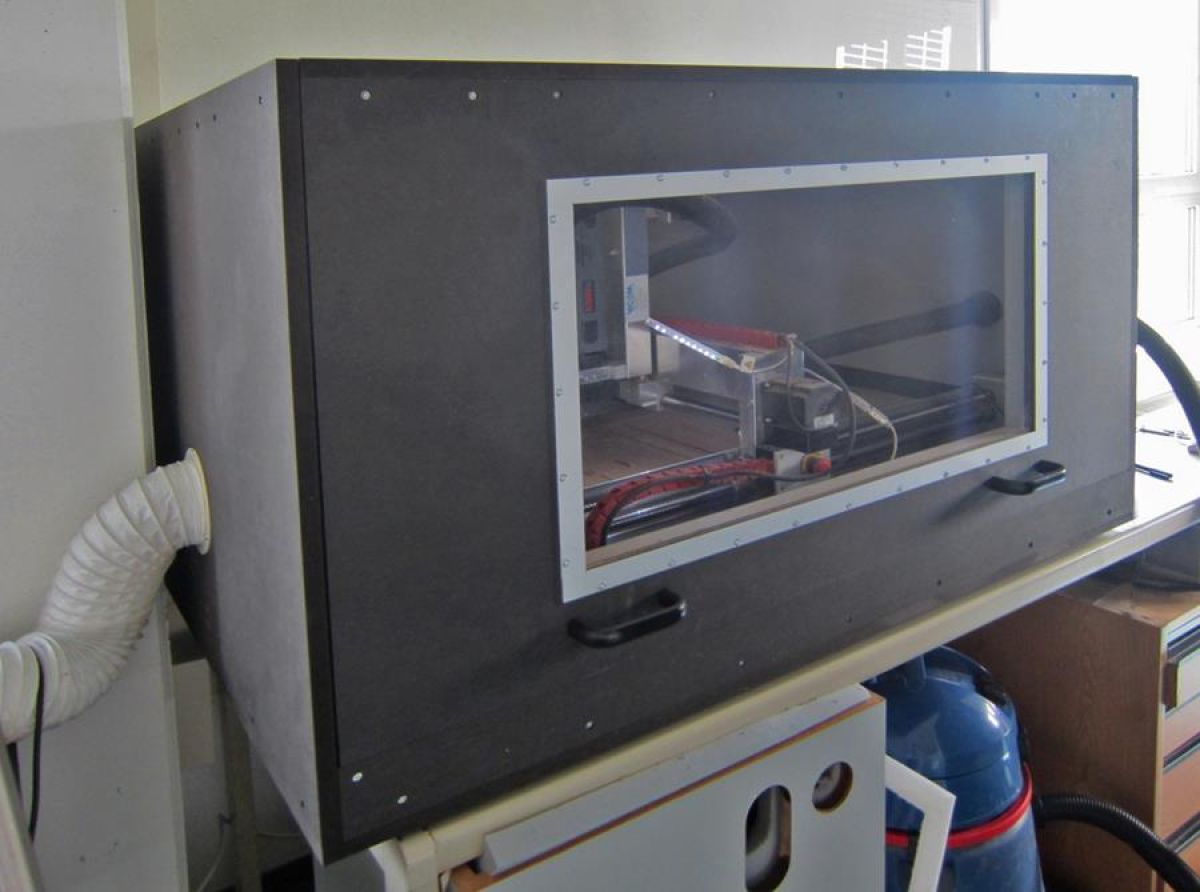

By using our sound insulation technology, the noise level of this milling machine has been significantly reduced. We also develop solutions for other machines and noise centers. Please contact us with your needs.

For loud machines, we design and build individual soundproof housings to significantly reduce the noise level. Here an extremely loud machine has been successfully made quiet. In an assembly hall for medical products, it was extremely annoying due to its very dynamic impact noises. First, the acoustic source had to be analyzed, then the soundproof housing could be designed and built. The impact noise of this machine has been reduced so much that operators can even work without hearing protection.

Recording studios require absolute silence in order to be able to properly assess sound and acoustics. Loud 19" units that produce a considerable level of noise with their fans can be extremely soundproofed with our know-how. In the example above, we made a "Green Hippo" inaudible (and it was really loud).